Work Visa & Job Guidance for Engineers in Germany

Introduction Germany, the economic heartland of Europe, is a global leader in engineering, innovation, and industry. Its reputation for precision…

📢 Hurry Up ! 🎓 Free Course Enrollment 🔥 Closing Soon ⏰

Industrial Engineering Insights

Explore the latest trends, techniques, and innovations in industrial engineering. From process optimization and lean manufacturing to emerging technologies like AI and automation, these articles dives deep into strategies that drive efficiency and productivity. Whether you’re a seasoned engineer or a curious learner, our expert articles provide valuable insights to help you stay ahead in the ever-evolving industrial landscape. Discover real-world applications, industry best practices, and transformative solutions tailored for professionals in manufacturing and beyond.

Introduction Germany, the economic heartland of Europe, is a global leader in engineering, innovation, and industry. Its reputation for precision…

The 5S methodology is a structured approach to workplace organization that enhances efficiency, safety, and productivity. Originating from Japan and rooted in lean manufacturing principles, 5S has found its way into a variety of sectors, including manufacturing, service industries, and even educational institutions. This guide will walk you through the essential steps of 5S, how to implement it across different industries, its significance in education, and the role of audits in maintaining continuous improvement.

Abstract Lean manufacturing has revolutionized the way industries operate, focusing on maximizing efficiency while minimizing waste. Rooted in principles that…

Abstract Lean manufacturing has revolutionized the way industries operate, focusing on maximizing efficiency while minimizing waste. Rooted in principles that…

Abstract Kaizen, a Japanese term meaning “change for the better,” is a philosophy that emphasizes continuous improvement in all aspects…

Abstract In today’s highly competitive business landscape, operational efficiency is crucial for maintaining profitability and sustainability. One of the most…

Abstract In today’s competitive landscape, Quality Management Systems (QMS) play a pivotal role in driving operational excellence and ensuring long-term…

Just In Time (JIT) production is a revolutionary approach to manufacturing that has transformed efficiency in various industries. At its core, JIT is centered around the idea of producing only what is needed, when it is needed, and in the exact quantities required, thereby minimizing waste and streamlining operations. This production methodology shifts the focus from mass production to a demand-driven system, reducing excess inventory, optimizing resource usage, and improving overall product quality. The JIT philosophy goes beyond simple production scheduling; it embodies principles such as continuous improvement (Kaizen) and waste elimination to create a lean and efficient manufacturing system. In this article, we will delve into the fundamental aspects of a just in time production, explore its key principles, and examine how it reshapes the way manufacturers approach efficiency and productivity in modern industries.

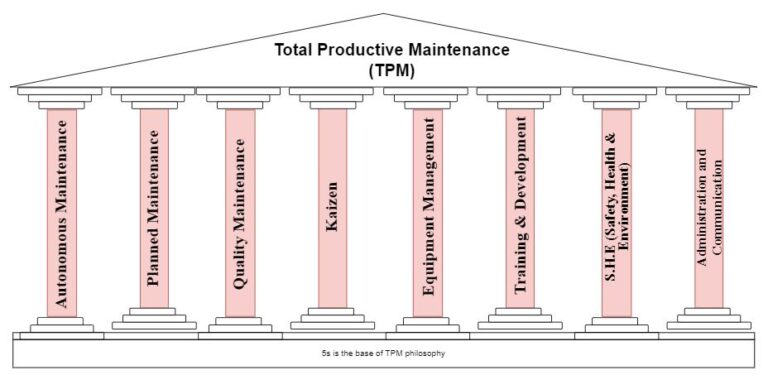

Abstract Total Productive Maintenance (TPM) is a comprehensive maintenance philosophy that aims to maximize the efficiency and productivity of equipment…